Horizontal Stabilizer Assembly

[69 hrs]

|

Horizontal Stabilizer Assembly [69 hrs] |

Horizontal Stabilizer: 7, 14, 20 & 22 September

|

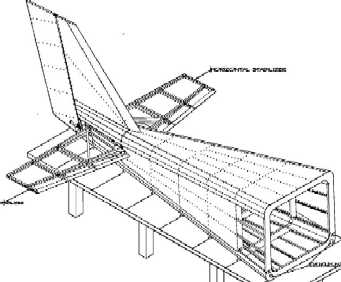

Before setting out the

horizontal stabilizer, read the plans very carefully and

lay out all the parts first as this is one of the most

complex constructions I have attempted to date. Cut to

lengths as per the drawings and set them out prior to

drilling. TIP: Make plenty of room on the workbench to construct both stabilizers. Drill all the holes and use clecos to hold the parts together but don't rivet any pieces until both horizontal stabilizers have been fitted into place to allow for changes in the angles. |

The

two stabilizers have been cut an drilled ready for

adjustment once they have been lifted into position. The

next stage is to make up temporary frames and fix them to

the bench so the stabilizers can rest on the frame at the

correct angle to the fuselage and workbench. |

|

|

To assist in the construction of

the horizontal stabilizer, build a temporary frame on

both sides of the fuselage to support both stabilizers to

the measurements above the workbench as specified in the

drawings and it will also keep the stabilizer at the

correct angle from the leading edge to the trailing edge. TIP: Before using clecos to clamp both stabilizers to the support frames, run a string line from stabilizer tip to the other stabilizer tip so the trailing edge remains aligned. |

The support

frames on both sides of the fuselage will allow you to

adjust the horizontal stabilizers to the angle and in my

case, I had to adjust several of parts so the edges

remained at right angles to the trailing while fitting

tight against the fuselage. |

|

|

Adjust measurements to all parts so the

horizontal stabilizer bracket is in-line with the metal

fuselage frame as this is what gives the stabilizer its

strength. TIP: Use as many clecos as necessary to hold components into place making sure both stabilizers are kept aligned, at the correct angel to the workbench as well as the centre line drawn along the side of the fuselage. This takes time, but it is important to spend the time so when they horizontal stabilizers are finally fixed to the aircraft, no further adjustments will be necessary. |

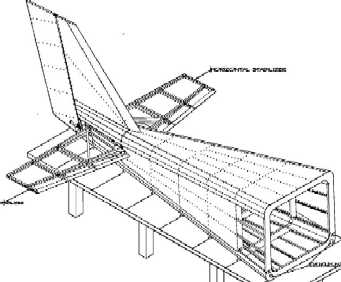

Time to start

riveting both horizontal stabilizers after pulling them

apart, deburring, wiping clean, spraying all surfaces

that come into contact with each other then putting all

the parts back together again. I will wait until the

cabin is completed and attached to the fuselage before

fitting the skins to the stabilizers, however all

attachement holes have been drilled. |

|

December 1, 2, 6 & 7

|

With the two stabilizer bolted into position

and aligned according to the drawings, mark out and drill

the top skin then use it as a template for the bottom

skin, then clamp them into position on the stabilizer

frame drilling the holes and clamping with clecos from

the fuselage out toward the tip, this will ensure the

skin remains tight against the frame. TIP: Only trim the edge that fits against the fuselage, leave the others as these can be trimmed when everyting is in place. Don't rivet until the elevator has been constructed. |

The marking

out and fitting of the leading edge will take some time

as it has to fit around the supporting barcket that holds

the stabilizer into position, then start drilling from

the fuselage out toward the outer edge so it remains a

tight fit against the support bracket. |

|